- ROLAND CUT STUDIO HELP HOW TO

- ROLAND CUT STUDIO HELP SERIAL KEY

- ROLAND CUT STUDIO HELP SERIAL NUMBER

- ROLAND CUT STUDIO HELP SOFTWARE

ROLAND CUT STUDIO HELP SERIAL NUMBER

I'm totally stuck - I can prove I have the cutter from its serial number etc.Įasy Cut Studio 4.1.0.5 Crack Version Full Free Download Easy Cut Studio. My GX-24 is now a door stop without the CutStudio software.

ROLAND CUT STUDIO HELP SOFTWARE

application tape for test cuts, Roland Software Package CD-ROM (CutStudio design software, plug-ins for CorelDraw. USCutter MH 34" Vinyl Cutter Plotter Bundle Sign Making Kit w/Software, Vinyl, Tape, Blades. Download Roland CutStudio software for plotters torrent or any other torrent from the Applications Windows. the latest internal programming for older, non-USB SummaCut plotters with Serial . register your MacSign CUT license using your Summa serial number Access.

Find all the latest downloads including drivers, firmware and software for our.

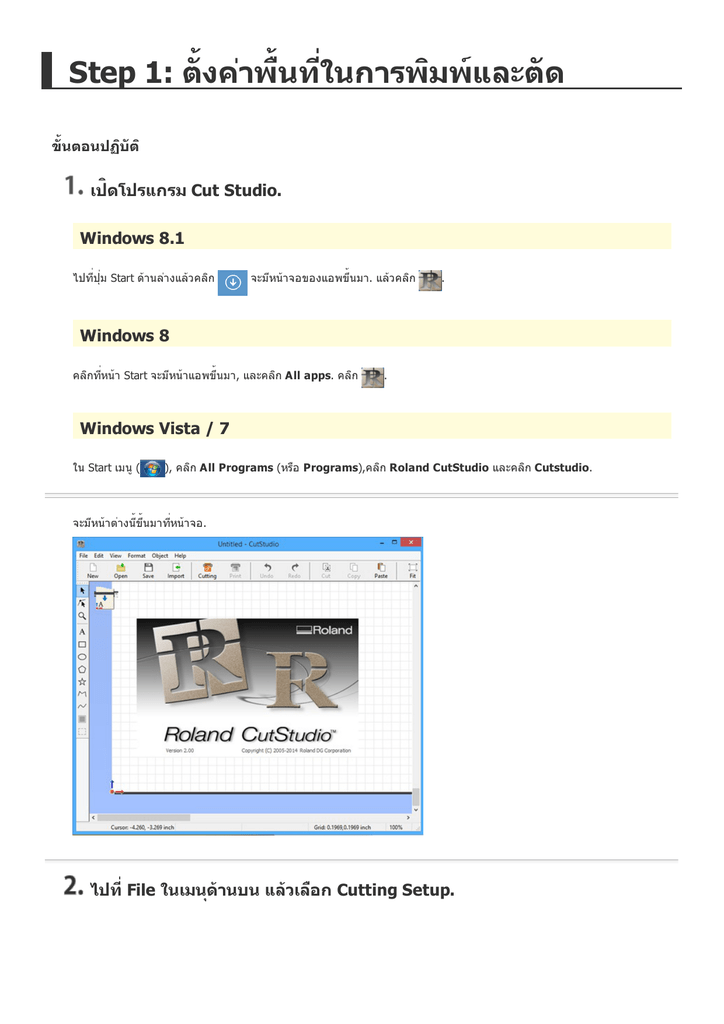

using an electronic cutting machine ( vinyl cutter and cutting plotter). Easy Cut Studio is the industry's premiere sign making and vinyl cutting. The provided high performance CutStudio software enables you via its tiling feature to produce larger signs of up . Back Product catalogue / Cutting Plotter / Cutting plotter. Plotter Roland Stika SV-8 (complete package).

ROLAND CUT STUDIO HELP SERIAL KEY

You will need to use the up and down arrows to move the blade into position to perform a test cut or to set the origin.Įditor’s Note: If you’re really into flowcharts, Roland has a PDF available, which details all of the menu options on the GX-24.Roland CutStudio Software For Plotters Serial Key = The machine assumes you know how much yardage you have and that you will input that information into the Cut Studio program if your design exceeds the cutting area available. Measures the distance between the pinch wheels and the blade will not move into any position once it has reached the far left. This is especially helpful if you are working with a scrap piece of material, or a one-yard cut. Measures the length and width of your material via all three sensors. This will accomplish a quick width measurement and will automatically put your blade in position for a test cut or to set the origin. Measures the distance between the pinch wheels and moves the blade to the far left edge of the material. When you first load material into the GX24, you will see on the display screen say, ‘Select Sheet’ and you have the option to choose Edge, Piece, or Roll by pushing the up or down arrow key.

The carriage head sensor measures the distance between the two pinch wheels, which is essentially, your workable width. The front and back apron sensors measure the length of your yardage. There is one sensor located on the front apron, one on the back apron (plastic bottom panels) and one in the carriage head.

ROLAND CUT STUDIO HELP HOW TO

The Roland GX24 has optical sensors to help detect what size film you’re working with, and if you learn how to work with the different settings on the cutter, you’ll be able to work with short cuts of vinyl and small pieces, too. Key settings on your cutter help you get the most out of your film and avoid headaches.īy Juliet Kalmeta, Technical Support Specialist The GX-24’s optical sensors allow it to determine what size of material you’re working with.

0 kommentar(er)

0 kommentar(er)